3d Egg and Dart Replica

For this project I was asked if I could replicate a 120 year old egg and dart molding at Harvard University’s Dunster House Renovation. The original was made of bone and every piece looked original and organic. This is usually the opposite of the 3d printing projects I encounter.

The main challenge was that these pieces would be used as fillers for the original moldings. Since the egg and dart at the store was not usable, I did my best to take all of this in account during the design process. My goal was to be precise but remain organic. I also wanted to do all the work in house on my own 3d printer, just because.

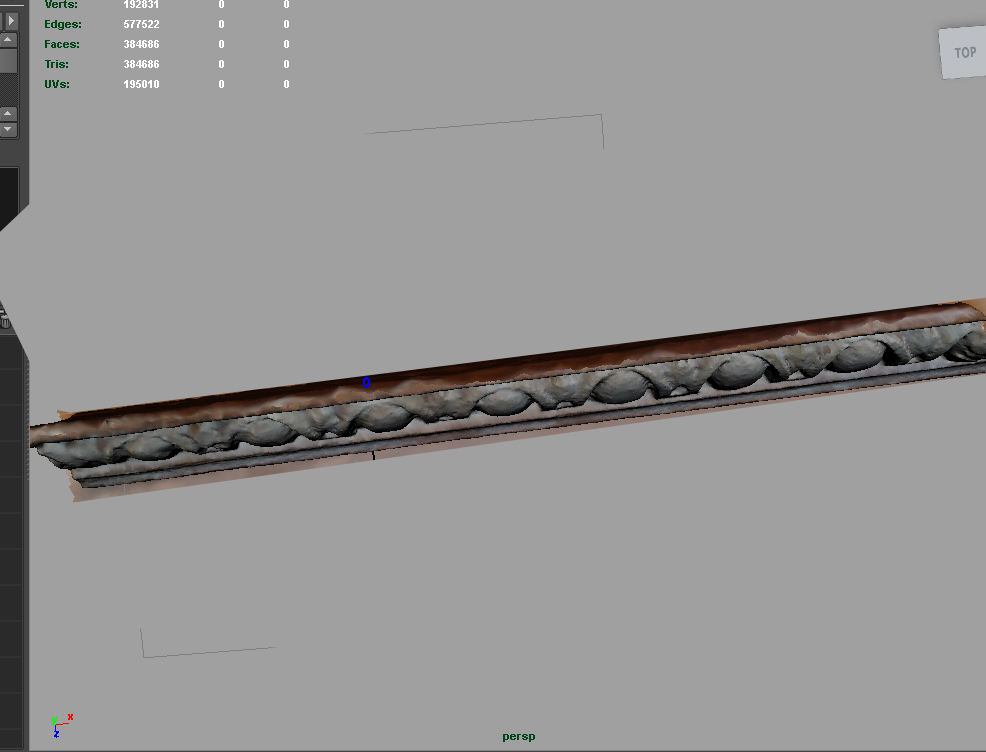

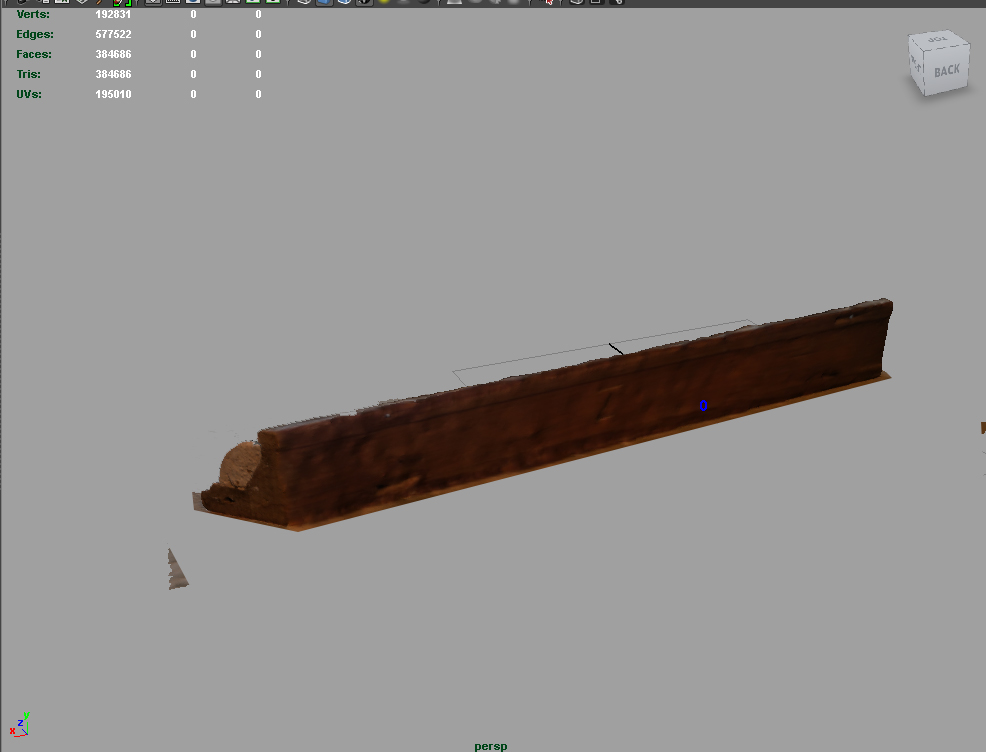

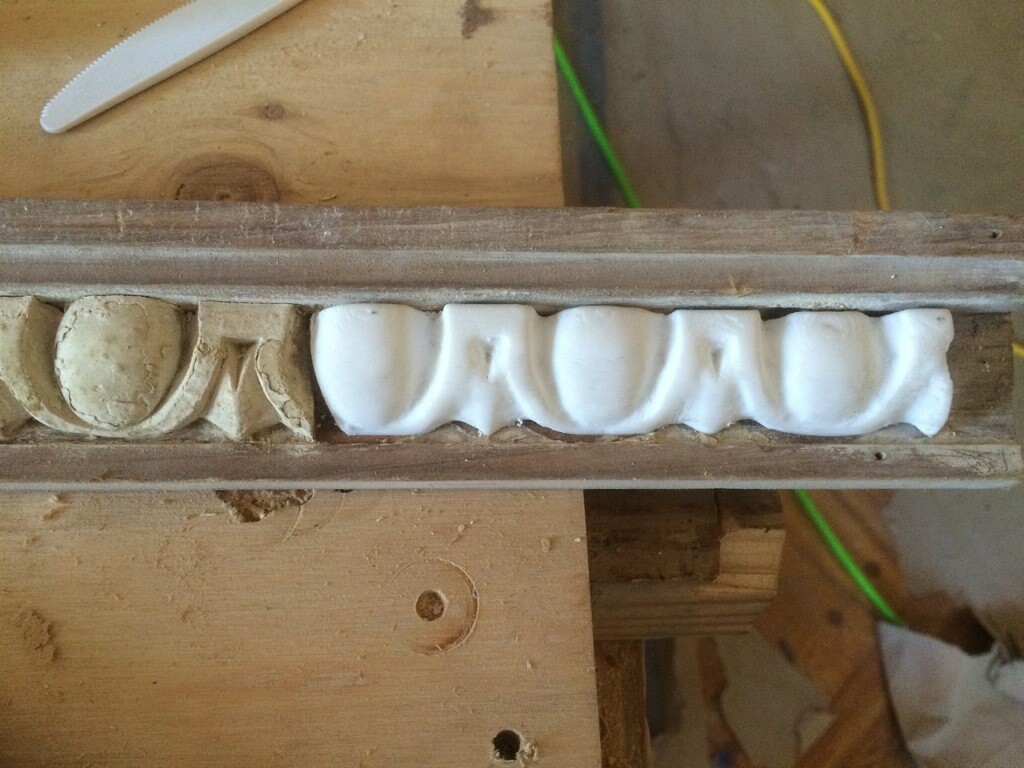

I got the initial two feet of the molding and I went to work with my scanner. There were pieces of wood attached so those had to be manually removed, I also decided to change the pitch of the back of the molding to a 90 degree angle so it would come out clean on the 3d printer with no supports.

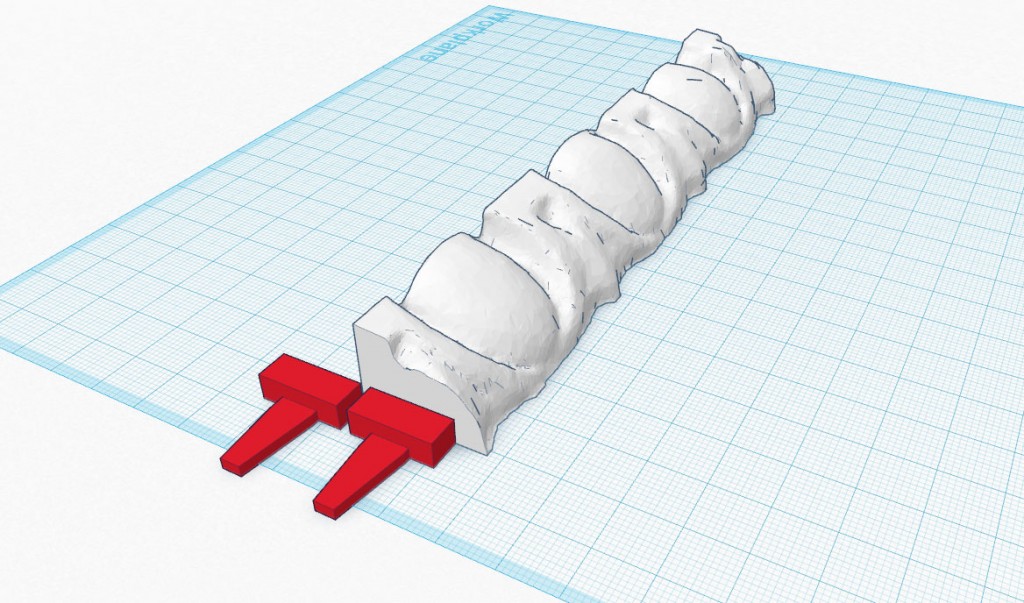

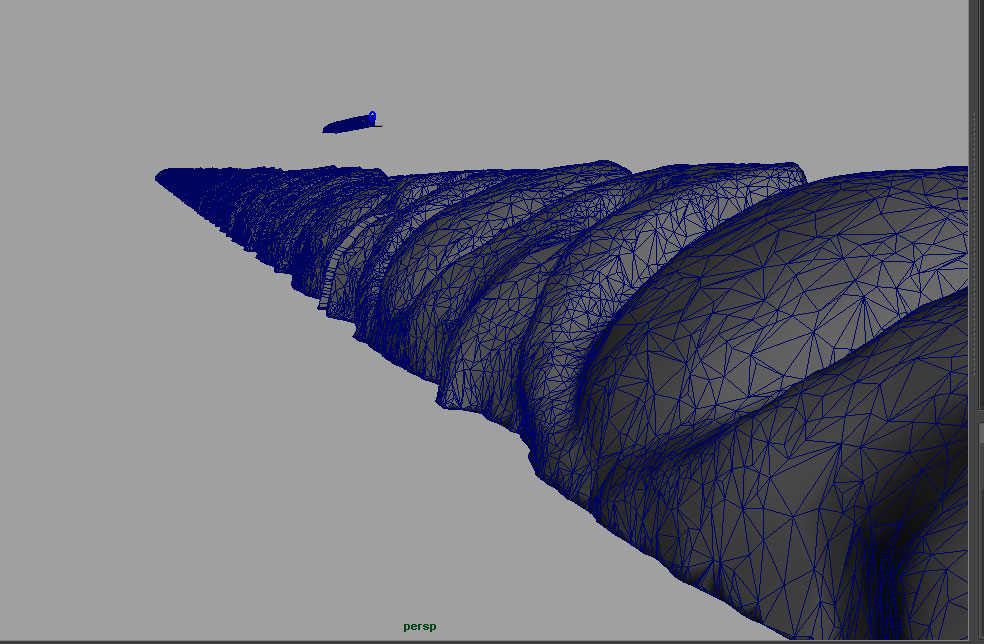

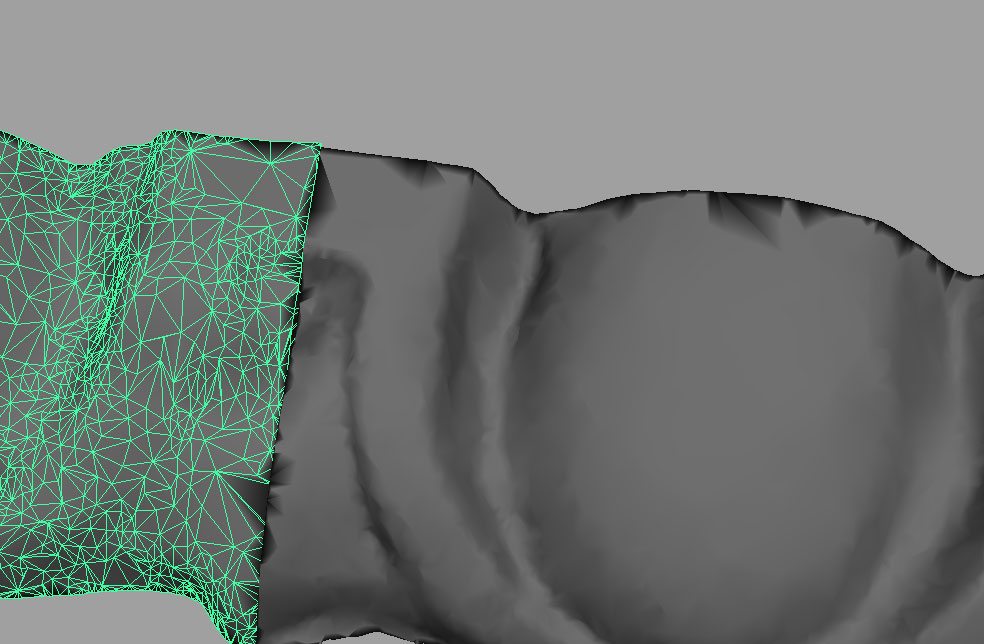

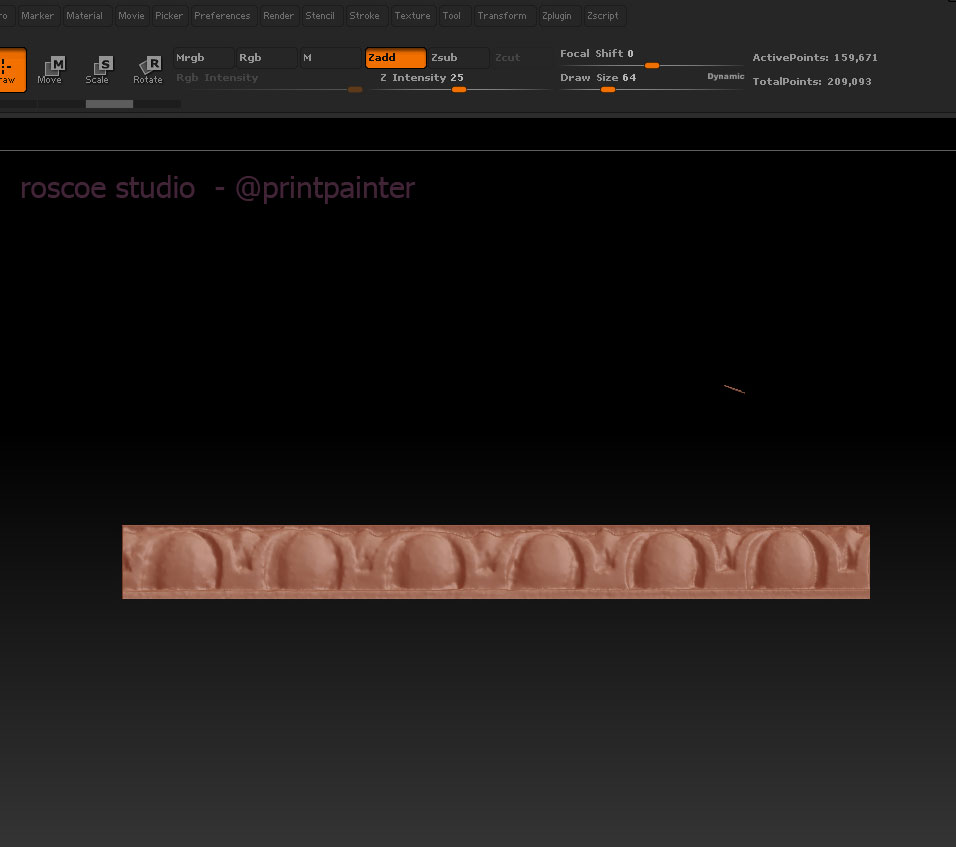

I figured that it would be best to start with a scan then take it into Maya. Now I had created two separate six inch sections so that they could fit on any 3d printer. The process after this was to print them out. My first two prints were not repeatable so I went back into Maya and lined up the verts one by one. After I had the twelve six inch sections, I decided to clean them up and make them more organic. I went through about fifteen sanding blocks, two dremel tips and some bondo that was then sanded again. I was nervous they would not mesh with the original pieces.

In the first shot you can see the original egg and dart pattern as well as half of the 3d printed replica’s, which are dremeled, but before sanding. I used a combination of techniques from manual modeling to 3d scanning with a Kinect V2. At the end of the day most of the modeling was done between Maya, Zbrush and hand carving. The reason for this is that the final piece had to be organic looking like the original moldings.